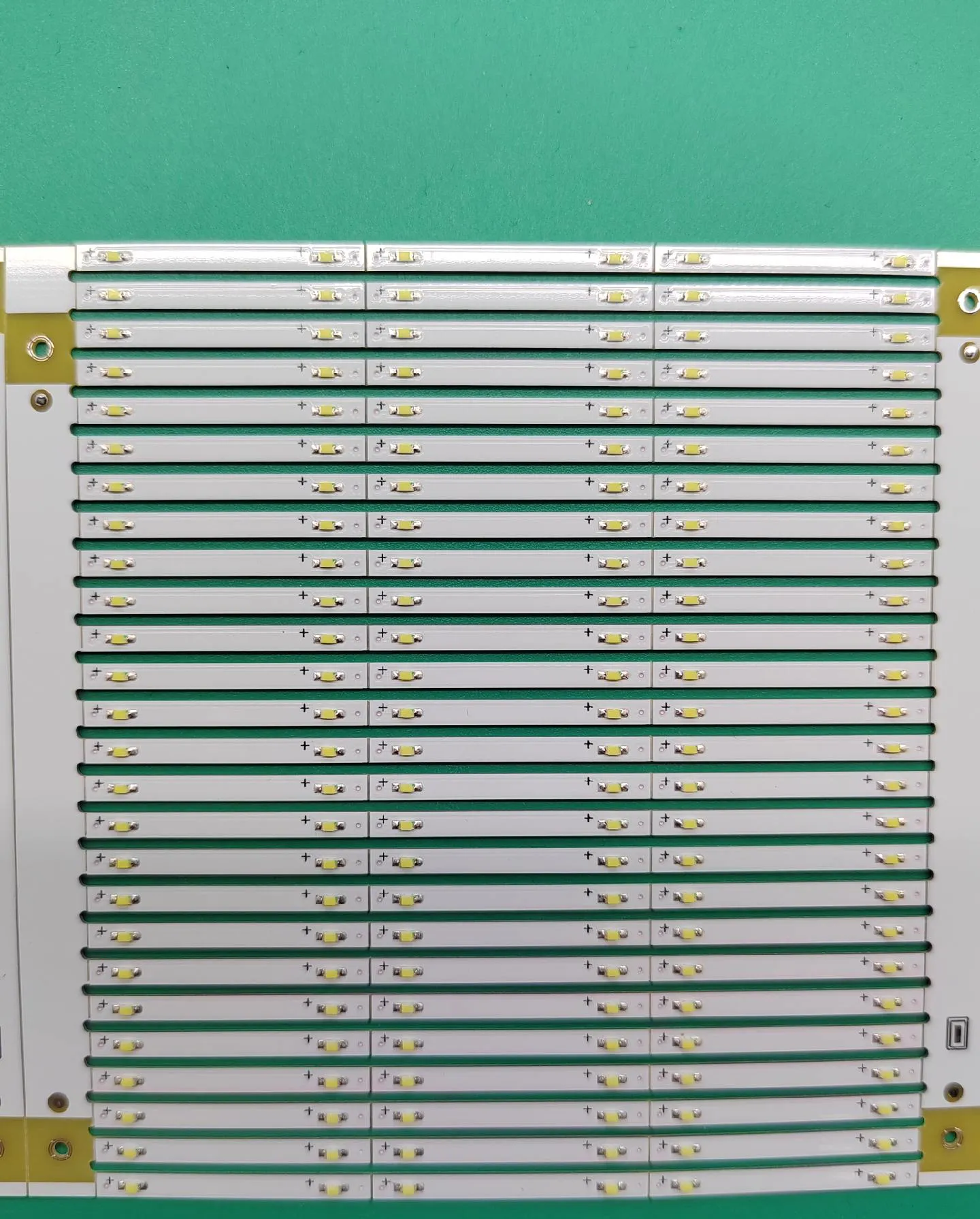

How many more processes does a multi-layer PCB have compared to single-layer and double-layer PCBs? Simply put, there are three more processes. The first is the production of inner layer graphics, the second is inner layer etching, and the third is lamination.

After cutting materials for single-layer and double-layer boards, drilling is done directly. For multi-layer boards, the inner layer graphics are first produced. In this step, the circuit graphics are accurately transferred to the inner copper foil. By applying photosensitive materials and going through processes such as exposure and development, the required patterns are perfectly presented.

Following that is the inner layer etching process. The copper not covered by the photosensitive material is etched away using a chemical solution, thereby clearly showing the inner layer circuit patterns.

In the lamination process, the core boards of each layer are firmly bonded together by combining the PP sheets of each layer, ensuring the overall quality of the multi-layer board. After lamination, the production process is in line with that of single-layer and double-layer boards.

Follow me to learn more about PCB knowledge.

8033 View