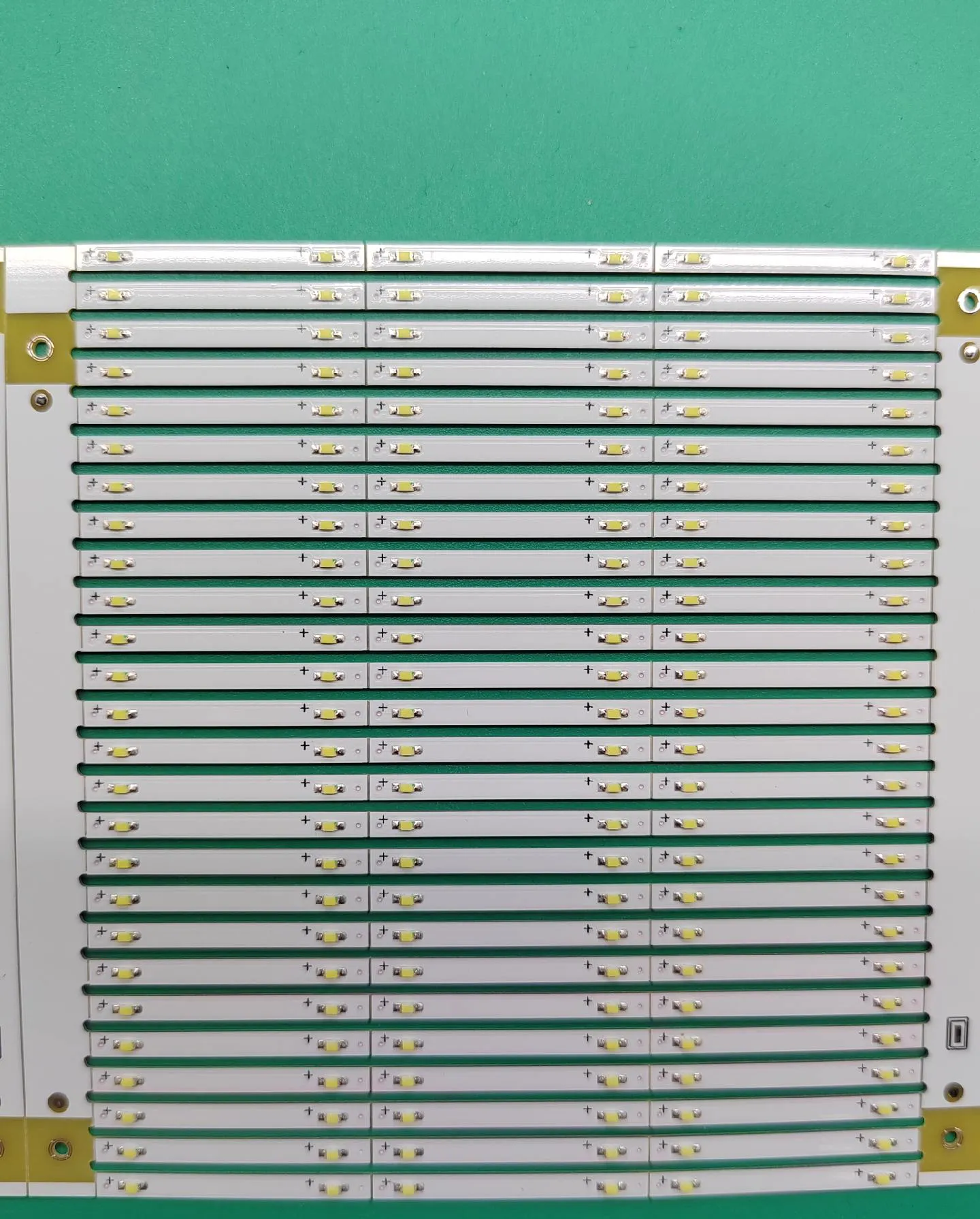

Ever wondered about the cost secrets behind the smooth folding experience of your new foldable phone? The thin PCB flexible board inside is a masterclass in balancing cost and performance.

The core cost driver of flexible PCBs lies in polyimide substrates, accounting for 30%-40% of total material costs. Thickness, brand, and material utilization are the three key factors. Thinner substrates enable smaller bending radii and slimmer end products, but each thickness grade adjustment can change costs by 15%-25%. Premium brands like DuPont and Ube command a 20%-40% price premium over domestic alternatives, yet deliver superior dimensional stability—critical for high-precision applications. Improving material utilization by just 1% can cut overall costs by 0.3%-0.5%.

Copper foil and layer count also play a vital role. Rolled copper, ideal for dynamic bending scenarios, costs 20%-35% more than electrolytic copper, which is perfect for static applications. Layer count impacts costs non-linearly: double-layer boards cost 30%-40% more than single-layer ones, while four-layer boards add another 50%-60% to double-layer costs, due to lower lamination yields and complex processes.

Reinforcement materials and shaping processes further affect costs. FR-4 is the most cost-effective reinforcement option, while stainless steel versions are 3-5 times pricier, suitable for heat dissipation or electromagnetic shielding needs. Mold punching is economical for mass production (5,000-10,000 pieces as the break-even point), while laser cutting is flexible for small batches.

The golden rule for cost control? Start from application scenarios. Dynamic bending requirements (100,000+ bends) demand expensive adhesive-free substrates paired with rolled copper, increasing material costs by 40%-60% but ensuring long-term reliability. The minimum bending radius is typically 6-10 times the substrate thickness—this simple rule guides optimal material selection.

In short, the most economical flexible PCB solution is never the cheapest material combination, but the one perfectly tailored to application needs.

8033 View