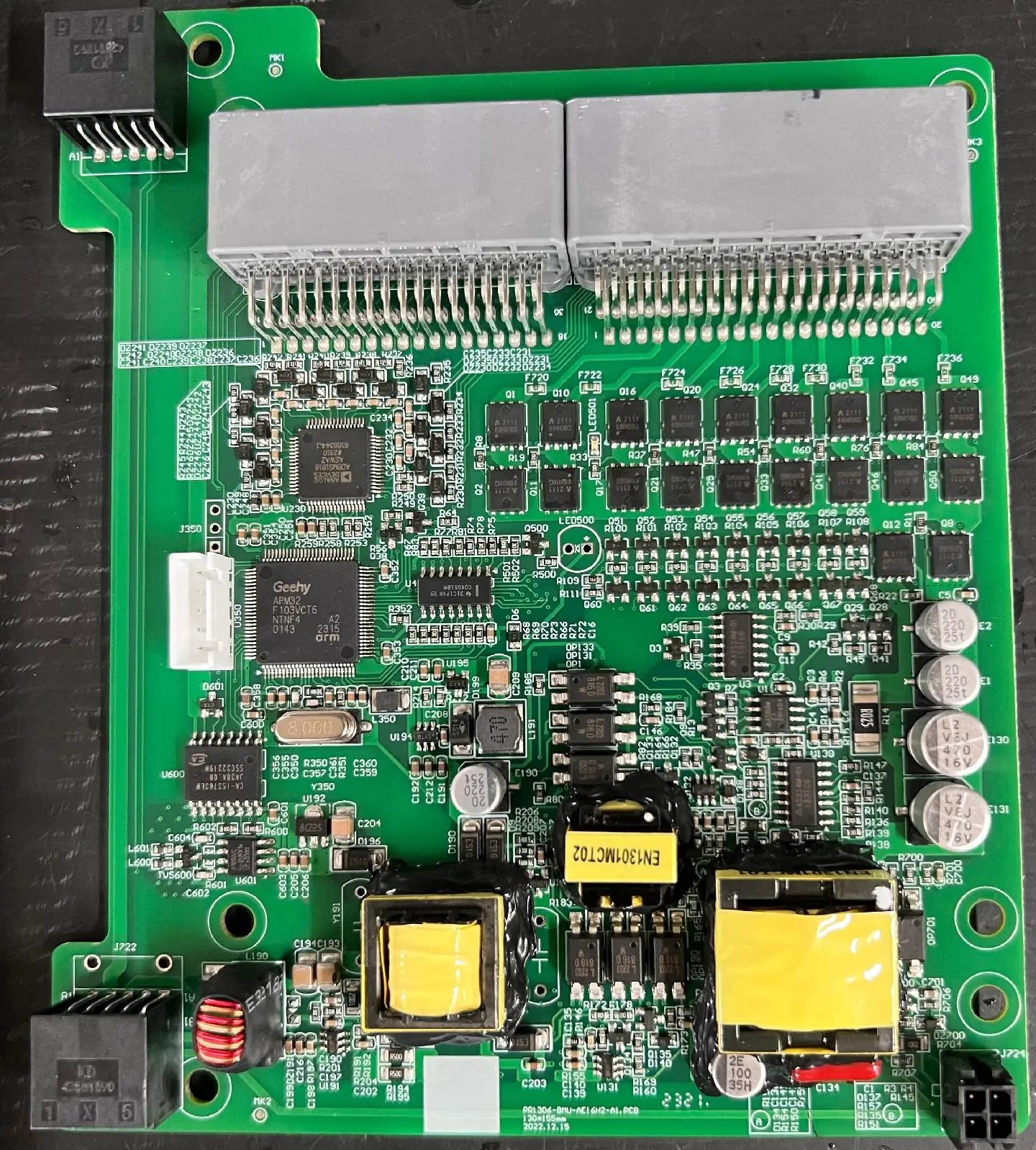

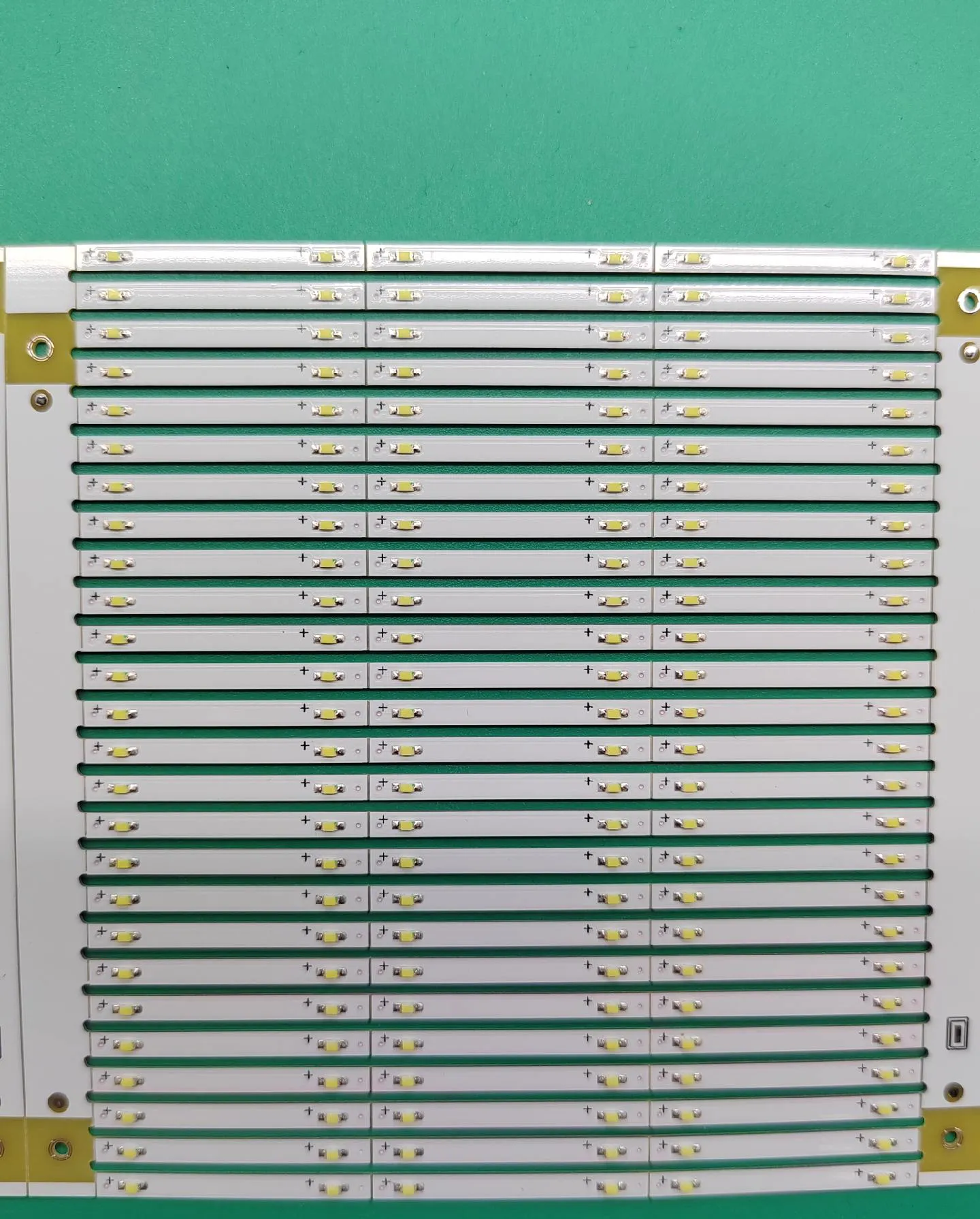

In the manufacturing process of PCB boards, the solder mask exposure step is crucial. Its purpose is to protect the parts that do not require soldering during the soldering process, preventing solder from forming unnecessary connections in these areas. This ensures the accuracy of solder joints and the stability of the circuit system.

The presence of the solder mask effectively avoids short circuits and incorrect soldering issues. Additionally, it provides a protective function, shielding the circuit from moisture, dust, and chemical substances, thereby enhancing the reliability of the circuit board and extending its service life.

Furthermore, the solder mask helps maintain the cleanliness and neatness of the circuit board's surface, making subsequent maintenance and inspection work more convenient.

8033 View